APPENDIX A - Analyses

A1: calculation of power requirement

This is the calculation of required power, using regular energy methods, to rotate the pinwheel at 12 rpm, while under maximum load. The calculated figure is 0.335 HP. The project is intended to be a robust piece of equipment, and a 0.5 HP motor is expected to be much more available than a 0.335 HP motor.

A2 : Calculation of shared axle diameter

This is the calculation of the diameter required for the axle to sustain the maximum load with a safety factor of 2. The calculated diameter needed, for an A36 steel rod to sustain to required loads, with a safety factor of 2, is about 1 inch.

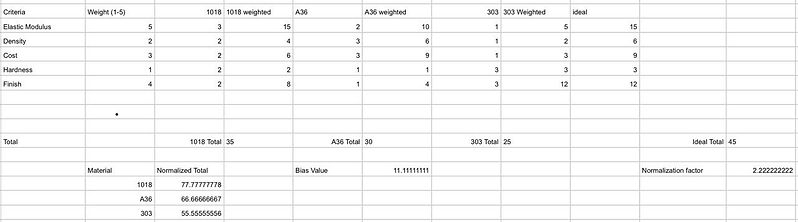

A3: Axle Material Decision Matrix

The last analysis determined the necessary diameter, with the assumed material of A36, for the shared drive axle. This is a decision matrix set up to evaluate some other material options. 1080 steel is the preferred option.

A4: Calculation of shear stress in pinwheel 1.66 in from foot wheel

This is just a check calculation. The value is less than 1 KSI so there’s nothing to worry about.

A5: Calculation of shear stress in pinwheel 4.4 in from foot wheel

This is just a check calculation. The value is less than 1 KSI so there’s nothing to worry about.

A6: Design check of foot wheel axle diameter by shear

This project will be using longboard wheels as the “foot wheels” longboard wheels spin on bearings will an inner race diameter of of 0.315 in. This calculation is a design check on the diameter, with a material choice of A36 steel. The shear stress is so relatively low that any steel would work. A36 is a good assumption.

A7: Design check of foot wheel axle diameter by normal stress.

This analysis is very similar to the previous one. The main difference being the type of stress being checked. This checks the normal stress due to bending.

A8: Calculation of battery specs

In research, this project has seen that nearly all motor solutions are intended to run on a 12v power supply. Motorcycle batteries are nearly all 12 volt batteries, and have a wide variety of available amperages.

A9: Calculation of wire gauge

After determining the type of battery to be used, easily available wire gauge charts were found on the internet and used to determine the appropriate gauge for this project.

A10: Design Check on Winch Torque.

Due to the very prohibitive cost of high torque gear motors, this project will use a consumer grade winch. This project, at absolute worst case scenario, requires less than 150 ft-lb of torque.

So a winch capable of 250 ft-lb at max should work well.